The maintenance method of the drum Printing Machine is crucial, which not only ensures the normal operation of the equipment, but also extends its service life

Here are some key maintenance steps and precautions:

Daily cleaning:

Clean the printing drum, ink bucket, water bucket, and other parts that come into contact with ink and water every day to ensure that there is no residual ink or water.

Regularly clean the dust and debris inside and outside the machine to keep it clean.

Lubrication and refueling:

Regularly lubricate each lubrication point of the machine to ensure the smooth operation of components such as bearings, chains, and guides.

Check and replace lubricating oil and grease according to the requirements of the user manual.

Maintenance of ink and water buckets:

Ink and water buckets should be cleaned regularly to avoid the accumulation of ink residue and scale.

Check the sealing of the ink and water buckets to ensure that there is no ink or water leakage.

Maintenance of printing drum:

Check the surface of the drum to ensure there are no scratches or dents, which can affect the printing quality.

Regularly clean and polish the drum to maintain its smooth and clean surface.

Electrical inspection:

Regularly inspect electrical circuits and connections to ensure they are not loose or damaged.

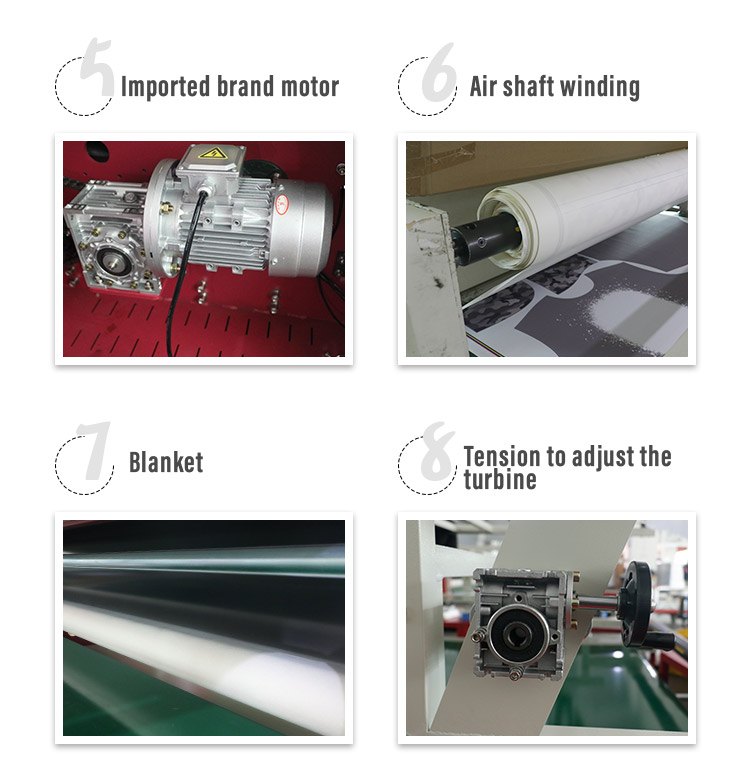

Clean the motor and electrical components to ensure good heat dissipation.

Regular inspection and adjustment:

Regularly check the accuracy of the machine, such as printing pressure, registration accuracy, etc., and make necessary adjustments.

Check the tightness of each component to ensure that there are no loose or detached parts.

Use appropriate consumables:

Using high-quality ink, paper, and plates not only improves printing quality, but also reduces wear and tear on the machine.

Training and operational standards:

Provide regular training to operators to ensure they understand the correct operating methods and maintenance requirements of the machine.

Develop and implement operating procedures to avoid damage to the machine caused by improper operations.

Shutdown maintenance:

If the machine is not used for a long time, it should be thoroughly cleaned and maintained, and rust prevention measures should be taken.

Regularly inspect and replace vulnerable parts, such as rubber sheets, printing plates, etc.

Equipment advantage

1. High-efficiency production: The large-diameter cylinder and high-precision digital control system configured by the equipment can achieve high-quality printing output.

2. High-quality printing effect: the equipment can effectively control the printing pressure and temperature to ensure the color accuracy and consistency of the printing effect.

3. Multiple adaptability: The equipment is suitable for various materials, including paper, film, vinyl, etc.

4. Advanced functions: Advanced functions such as automatic tension control, pneumatic expansion axis, and user-friendly interface have improved efficiency and made production easier.

5. Quality assurance: The equipment is made of high-quality materials, well-made, long-term stable operation, and high-quality printing effect.