Manufacturing an A3 T-shirt Printing Machine involves several key mechanical components and manufacturing processes to ensure its functionality and reliability

Below are the main aspects of manufacturing an A3 T-shirt printing machine:

Below are the main aspects of manufacturing an A3 T-shirt printing machine:

Frame and Structure: The frame of the printing machine serves as the structural support for all other components. It is typically made from sturdy materials such as steel or aluminum to provide stability and durability. Precision machining techniques are used to fabricate the frame to exact specifications, ensuring proper alignment of components during assembly.

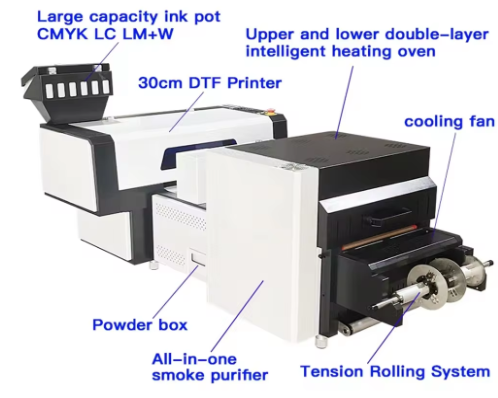

Printing Mechanism: The printing mechanism is the heart of the machine, responsible for transferring ink onto the fabric surface. It typically consists of a printing platen, printhead carriage, and ink delivery system. The platen holds the garment in place during printing, while the printhead carriage moves horizontally across the platen, depositing ink onto the fabric. Precision machining and assembly are required to ensure smooth movement of the printhead carriage and accurate ink deposition.

Printhead Assembly: The printhead assembly houses the inkjet printheads responsible for dispensing ink onto the fabric. These printheads contain tiny nozzles that eject ink droplets onto the fabric surface with precision. Manufacturing the printhead assembly involves precision machining of components and delicate assembly processes to ensure proper alignment and functionality of the printheads.

Ink Delivery System: The ink delivery system supplies ink from the ink reservoirs to the printheads. It typically includes ink tubes, valves, and pumps to regulate ink flow and pressure. Precision manufacturing techniques are employed to fabricate these components, and stringent quality control measures are implemented to prevent ink leakage or clogging.

Control Electronics: The control electronics of the printing machine include circuit boards, sensors, motors, and actuators responsible for controlling various functions such as printhead movement, ink delivery, and temperature regulation. Surface mount technology (SMT) is often used in the manufacturing of circuit boards to ensure compactness and reliability. Precision assembly techniques are employed to integrate electronic components into the machine, and thorough testing is conducted to verify proper functionality.

User Interface: The user interface of the printing machine includes control panels, displays, and input devices that allow operators to interact with the machine and control its operation. Manufacturing the user interface involves assembling components such as buttons, switches, and touchscreens into a cohesive interface that is intuitive and user-friendly.

Safety Features: A3 T-shirt printing machines are equipped with various safety features to protect operators and prevent accidents. These may include emergency stop buttons, safety interlocks, and protective enclosures. Manufacturing these safety features involves integrating mechanical and electronic components to ensure reliable operation and compliance with safety standards.

Assembly and Testing: Once all components are manufactured, they are assembled into a complete printing machine. Assembly processes involve meticulous attention to detail to ensure proper alignment and fit of components. After assembly, the machine undergoes rigorous testing to verify functionality, print quality, and reliability under various operating conditions.

In summary, manufacturing an A3 T-shirt printing machine requires expertise in precision machining, electronics assembly, and quality control to produce a reliable and high-performance printing solution. Each component must be carefully manufactured and assembled to exacting standards to ensure the machine's functionality and durability in printing custom designs onto T-shirts and other garments.