Textile Industry Transformation: Textile Laser Cutting Machine Pioneers Precision and Efficiency

In a paradigm-shifting advancement, the textile industry is witnessing a revolutionary transformation propelled by the Textile Laser Cutting Machine. This cutting-edge technology is redefining the landscape of textile manufacturing with its unprecedented precision and efficiency.

Traditionally, the textile sector has grappled with the limitations of mechanical cutting tools, leading to inefficiencies and substantial material wastage. Enter the Textile Laser Cutting Machine – a technological marvel that leverages laser precision to elevate the industry's standards.

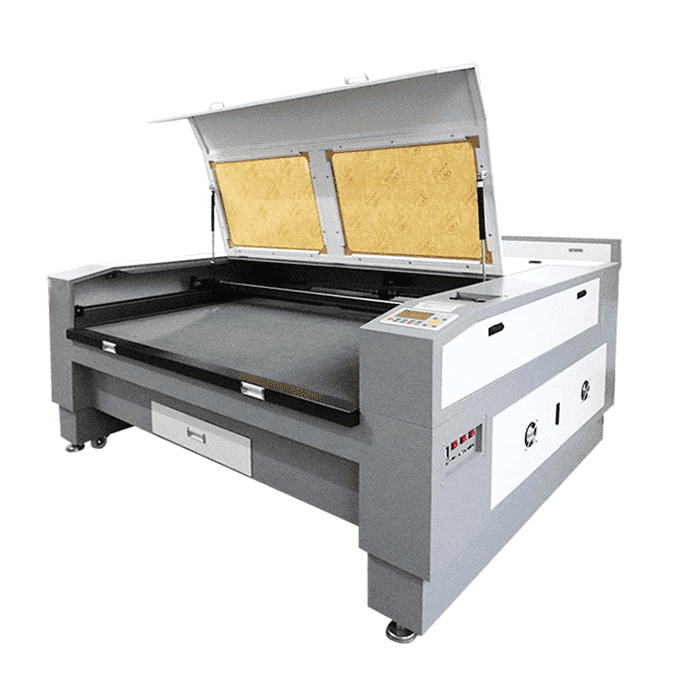

This innovative machine operates on the principle of high-energy laser beams, replacing traditional blades with a non-contact cutting method. The result is a level of accuracy and intricacy that was once unimaginable. The laser's ability to precisely target and cut fabrics not only enhances the quality of the finished product but also significantly reduces material waste.

One of the standout features of the Textile Laser Cutting Machine is its versatility. It seamlessly handles a myriad of textiles, from common fabrics like cotton and linen to more delicate materials such as silk. The machine's adaptability extends to intricate patterns and designs, offering manufacturers the flexibility needed for customized and high-end textile production.

The environmental impact of this cutting-edge technology cannot be overstated. By minimizing material waste and optimizing production processes, the Textile Laser Cutting Machine contributes to a more sustainable and eco-friendly textile industry. This reduction in waste not only aligns with environmental goals but also translates to cost savings for manufacturers.

The integration of this state-of-the-art technology is propelling the textile industry into a new era of efficiency and creativity. Manufacturers adopting the Textile Laser Cutting Machine are experiencing shorter production cycles, increased output, and improved product quality. As a result, the industry is witnessing a surge in customized and intricately designed textiles that cater to evolving consumer demands.

Moreover, the Textile Laser Cutting Machine is fostering innovation in design and manufacturing. Its ability to handle complex patterns with ease has opened up new possibilities for textile designers, allowing them to push the boundaries of creativity and deliver products that stand out in a competitive market.

In conclusion, the Textile Laser Cutting Machine is not just a technological advancement; it's a catalyst for change in the textile industry. Its precision, efficiency, and environmental benefits are propelling manufacturers towards a more sustainable and competitive future. As this cutting-edge technology continues to gain traction, we can expect a profound and lasting impact on the way textiles are designed, produced, and consumed. The Textile Laser Cutting Machine is truly at the forefront of a textile revolution, shaping the industry for years to come.