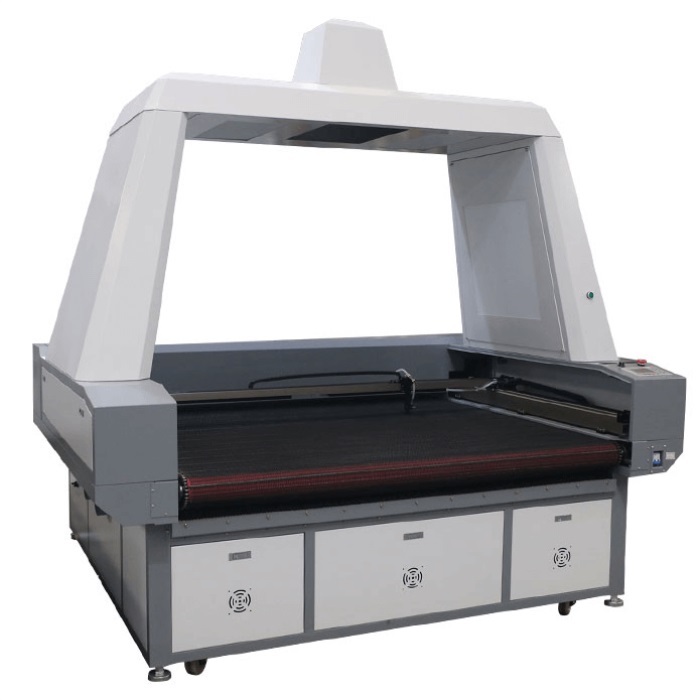

An edge-finding Laser Cutting Machine is a type of Laser Cutter that uses sensors to detect the edges of the material being cut. This allows for precise cuts and reduces the risk of cutting into the wrong area of the material.The process involves placing the material on the cutting bed and positioning the laser cutter head at a distance from the material. The laser cutter head is equipped with sensors that scan the surface of the material and detect its edges. Once the edges are identified, the laser cutter head adjusts its position and angle to align with the edge, and the cutting process begins.

Edge-finding Laser Cutting Machines are commonly used in industries that require precise and intricate cuts, such as in the manufacturing of electronics, automotive parts, and medical devices. They can cut a variety of materials, including metals, plastics, and fabrics, and offer high accuracy and efficiency in the cutting process.

A Laser Cutting Machine uses a combination of computer software and hardware to determine where to cut. Here is an overview of the process:

1.Designing the File: The first step in laser cutting is to design the file that contains the cutting pattern. This can be done using a variety of software programs, such as Adobe Illustrator, AutoCAD, or Inkscape. The file is typically saved in a vector format, which contains lines, curves, and shapes that the laser cutter can interpret.

2.Loading the File: Once the file is created, it is loaded into the laser cutter's software program, which converts the vector data into machine-readable code.

3.Setting Parameters: The operator then sets the parameters for the cut, such as the power and speed of the laser beam, the type of material being cut, and the depth of the cut.

4.Previewing the Cut: The software program then displays a preview of the cut on the computer screen, allowing the operator to make any necessary adjustments before starting the cutting process.

5.Cutting: Once the parameters are set and the operator is satisfied with the preview, the laser cutter begins the cutting process. The laser beam follows the vector lines and shapes in the file, cutting the material according to the predetermined pattern.

6.Completion: Once the cutting is complete, the operator removes the cut material from the laser cutter's work area.

Overall, a laser cutter uses a combination of software and hardware to precisely follow the vector patterns in a design file and create the desired cut. The operator sets the parameters for the cut, but it is the laser cutter's software and hardware that determine the exact location and path of the laser beam.