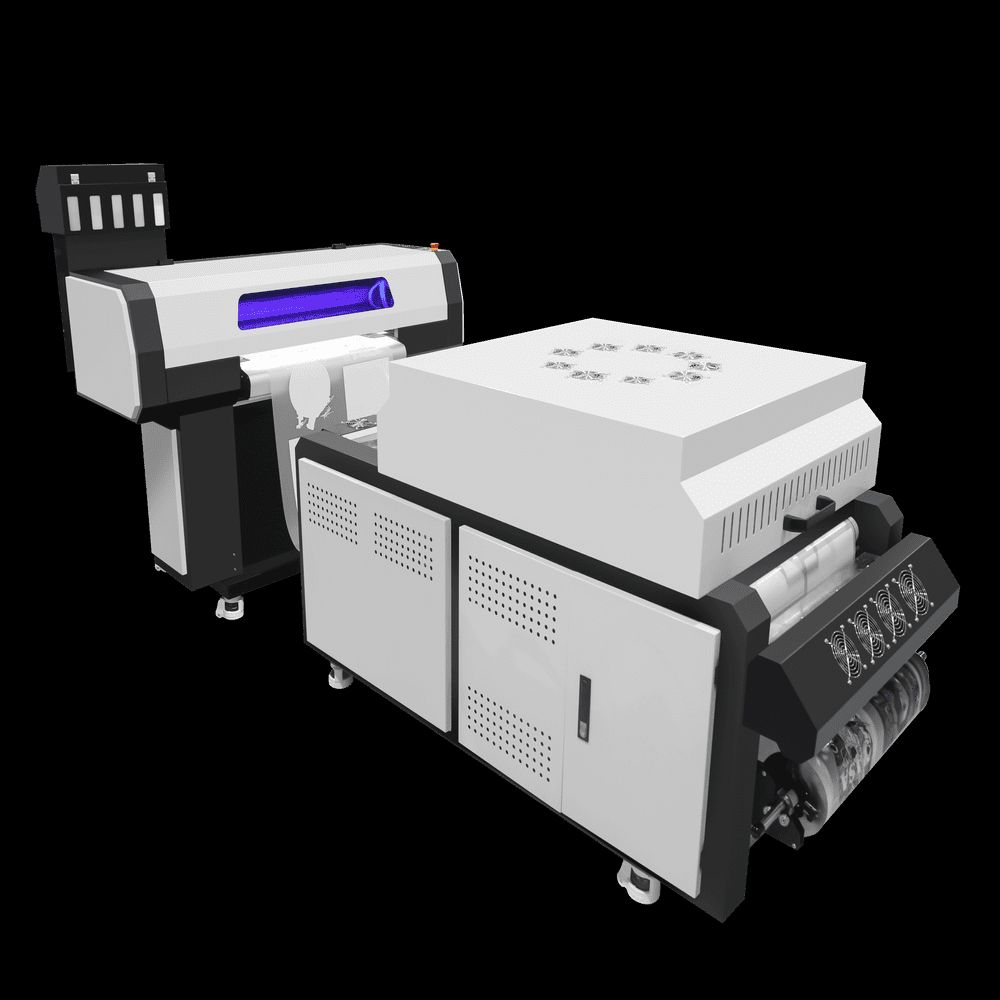

Powder Shaker Machine, is a machine used to apply powder evenly on the surface of an object. Its main working principle is to effectively disperse and adhere the powder evenly to the target object by means of a vibrating or rotating mechanism. This type of equipment is used in several industries, especially where precise control of powder coating thickness and uniformity is required, such as printing and coating industries.

![]() Features:

Features:

Uniform Coating: The machine effectively disperses and adheres the powder evenly to the target object, ensuring a uniform and consistent coating layer.

Precise Control: Powder Shaker Machines usually have a precise control system that can adjust the intensity, frequency and time of vibration or rotation to control the thickness and speed of powder coating to meet the needs of different applications.

Efficient operation: The machine is able to complete powder coating tasks quickly and continuously, increasing productivity.

Wide Adaptability: The Powder Shaker Machine is suitable for a wide range of materials and coating targets, and can be adapted to different powder characteristics and coating requirements.

Safe and reliable: The equipment is usually designed with safety protection measures, such as overload protection, emergency stop device, etc., to ensure the safety of the operator and the stable operation of the equipment.

Power:

Power:

6KW power, providing ample power support.

Vibration Motor:

Utilizes motor vibration technology to ensure even powder shaking.

Automatic Vibration Return:

Equipped with automatic bounce-free function during powder shaking, improving production efficiency.

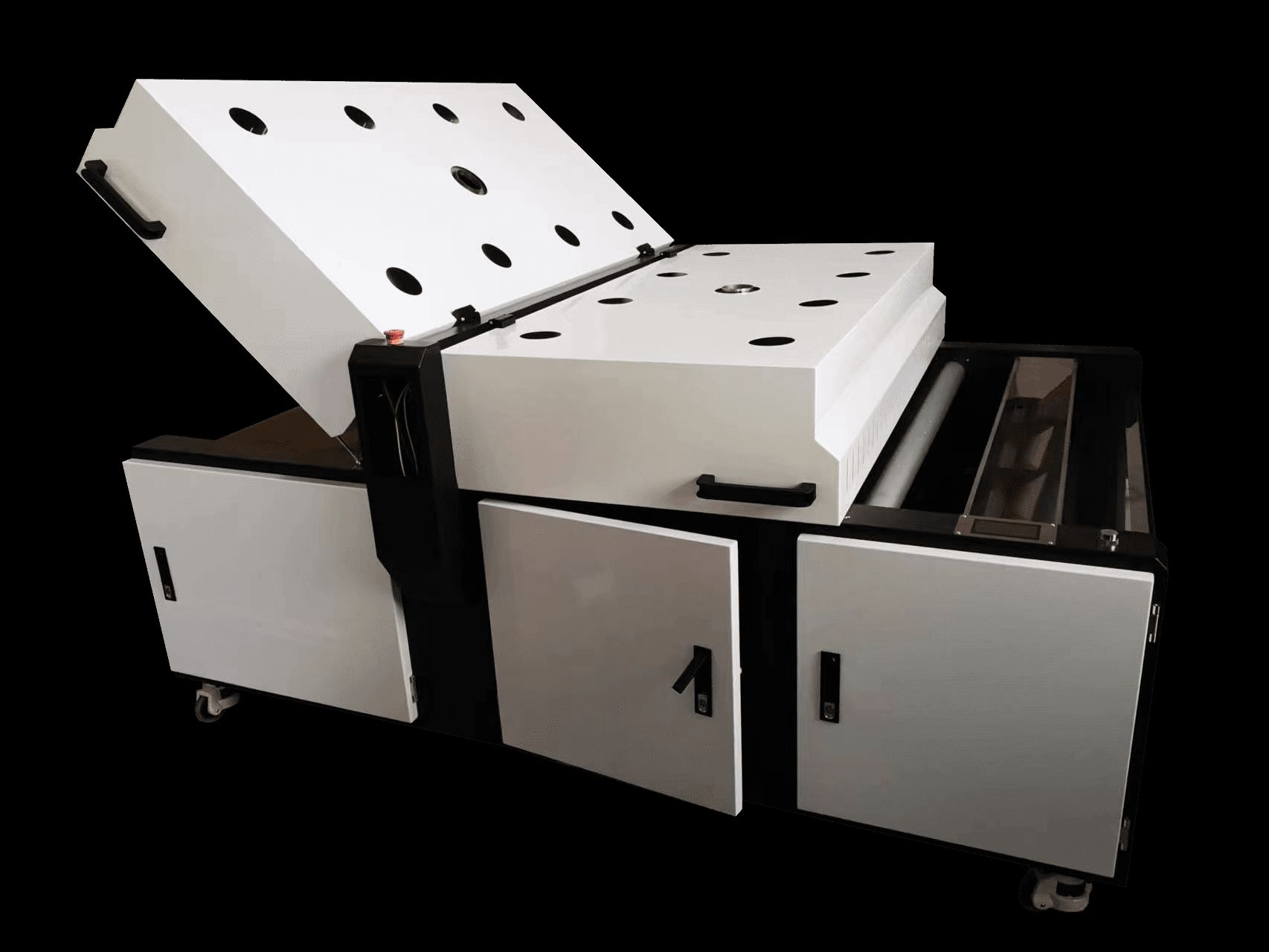

Double Ovens:

Features front and back heating double ovens for rapid and constant temperature heating.

Constant Tension Induction System:

Adopts a constant tension induction system to ensure stability in film take-up and feed.

Operation Modes:

Supports both manual control and automatic control modes, flexibly adapting to different needs.

Mesh Belt:

Uses a drum suction operation mesh belt to ensure smooth operation.

Automatic Deceleration to Prevent Deformation:

Includes automatic deceleration function to effectively prevent heating film deformation.

Film Cutting:

Utilizes constant weight automatic sensing for dusting, maintaining a clean operational environment.

Feeding Size:

1300mm

Technical Specifications:

Machine Weight: 632KG

Packing Weight: 777KG

Machine Size: 234182234cm

Packing Size: 230199115 cm, CBM: 5.264

Fields

Paint and Coating Industry: In the paint manufacturing and coating process, Powder Shaker Machine is used to uniformly apply powder coatings to the surface of workpieces such as metals, plastics, wood, etc. for aesthetic, protective and functional coating formation.

Powder Metallurgy Industry: In the field of powder metallurgy, the machine is used to uniformly mix and coat metal powders to manufacture metal parts or assemblies such as powder metallurgy gears, bearings, etc.

3D Printing Technology: In the 3D printing process, the Powder Shaker Machine can be used to spread the powder material uniformly on the printing platform to provide precise and consistent powder thickness for subsequent print layers

Food Processing Industry: During certain food processes, such as the creation of powdered flavorings, nutritional supplements or food additives, Powder Shaker Machines can be used to uniformly mix or coat powders onto food surfaces.

Chemical and Pharmaceutical Industries: In chemical and pharmaceutical manufacturing, Powder Shaker Machines can assist in the mixing, drying and coating of powders to ensure product quality and productivity.

Electronics & Semiconductor: In the electronics and semiconductor manufacturing industry, the machine can be used to apply powdered materials to electronic components or substrates to meet specific electronic performance requirements.