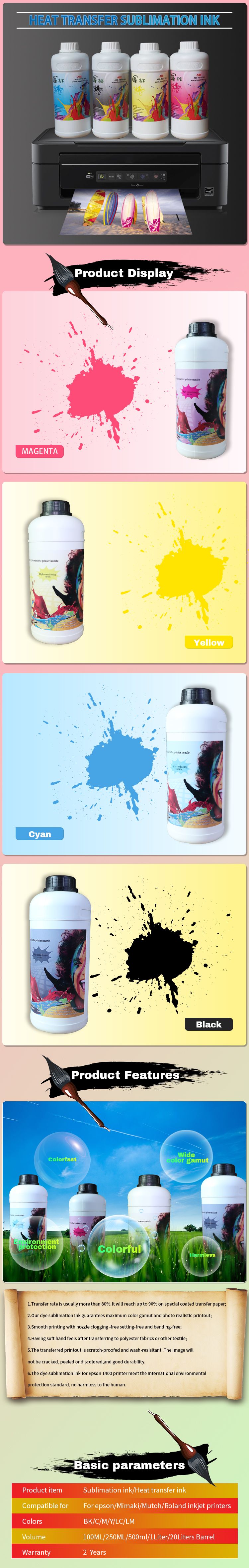

Thermal transfer ink, sublimation ink, dispersion ink

- Category:Sublimation ink

- Product name: High Quality Heat Transfer Printing Ink

- Printing Type: Digital printing

- Advantage: Environment Protection

- Application: Cotton fdigital inkjet cotton fabrics printer

Sublimation Ink

There are two main technologies in garment printing: direct inkjet printing and sublimation transfer printing. Sublimation transfer printing is the mainstream technology in garment printing. Due to its relatively simple process and the diverse types of fabrics it can handle, sublimation transfer printing has always dominated fabric decoration techniques.

The core steps of sublimation transfer printing include printing on sublimation paper and transferring the ink to the fabric. Printing on the sublimation paper is the first step that affects the stability and color vibrancy of the sublimation transfer process. Choosing the right sublimation ink has a decisive impact on the quality control of subsequent processes.

Sublimation ink is liquid and is generally supplied in 1L plastic bottles. It is poured into the inket printer's ink cartridge during use. The ink is ejected under high pressure and controlled by the Inkjet printer's built-in program, quickly solidifying on the sublimation paper surface. During the transfer process, under the influence of heat and pressure, the ink is transferred to the fabric in a sublimated state.

Characteristics of Dye Sublimation Ink:

Thermal Responsiveness: At high temperatures of 180-220℃, it transforms directly from a solid/liquid state to a gaseous state, detaching from the paper carrier. This is crucial for successful transfer printing.

Penetration: Gaseous dye molecules can penetrate the gaps between fabric molecules and bond with the material upon cooling.

Color Stability: The pigments in the ink are not easily decomposed under heat and pressure, maintaining minimal color loss.

Colors of Dye Sublimation Ink:

The base colors are the four primary colors of CMYK, but advanced colors with a wider color gamut can also be added according to user needs.

The four primary colors are: Cyan, Magenta, Yellow, and Black. Based on the additive principle of color mixing, these four primary colors can be mixed to create most colors visib

Product Features:

1.Transfer rate is usually more than 80%.It will reach up to 90% on

special coated transfer paper;

2.Our dye sublimation ink guarantees maximum color gamut and photo realistic printout;

3.Smooth printing with nozzle clogging -free setting-free and bending-free;

4.Having soft hand feels after transferring to polyester fabrics or other textile;

5.The transferred printout is scratch-proofed and wash-resisitant .

The image will not be cracked, peeled or discolored,and good durability.

6.The dye sublimation ink for Epson 1400 printer meet the international

environmental protection standard, no harmless to the human.

INQUIRY

CATEGORIES

- Inkjet printer

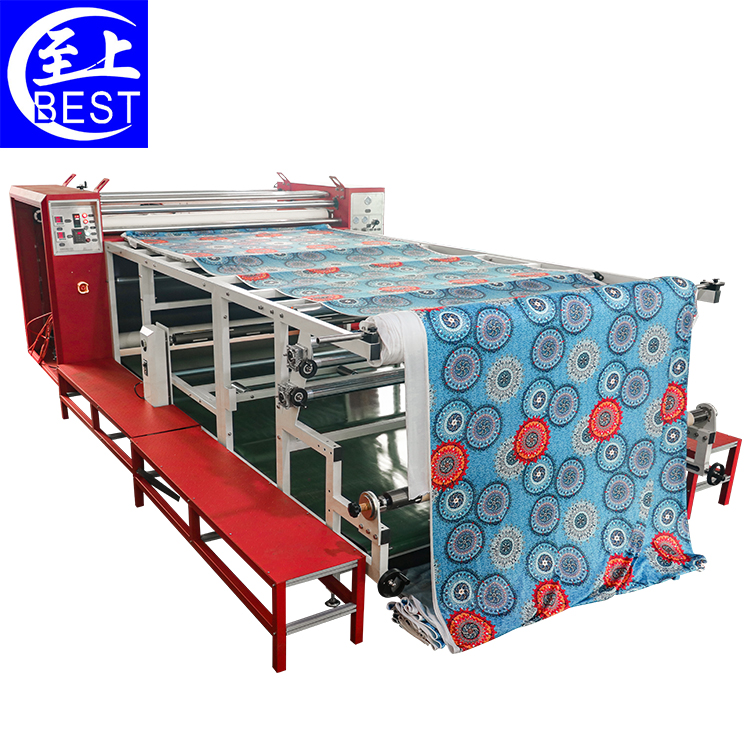

- Roller transfer machine-200mm

- Roller sublimation machine-420mm

- Roller sublimation machine -610mm

- Roller sublimation machine-800mm

- Roller sublimation machine-1000mm

- Laser cutting machine

- Heat press machine

- Ribbon zipper heat transfer machine

- Cloth rolling machine

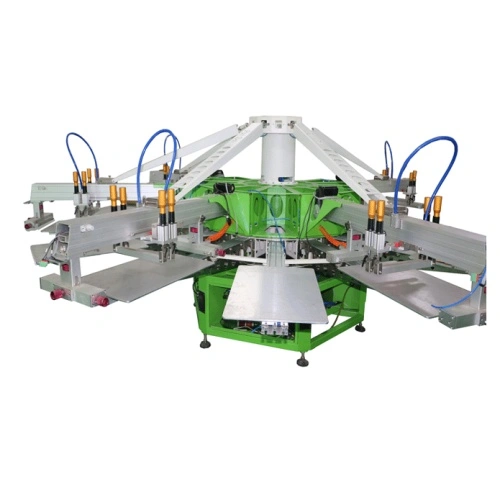

- Screen printing machine

- Paper and ink

- Spare parts

LATEST NEWS

CONTACT US

Name: lusa zhong

Mobile:+86 13829127980

Tel:+86 13829127980

Whatsapp:008613829127980

Email:sales@zsheatpress.com

Add:Fuma Road, Humen Town, Dongguan City, Guangdong Province, China