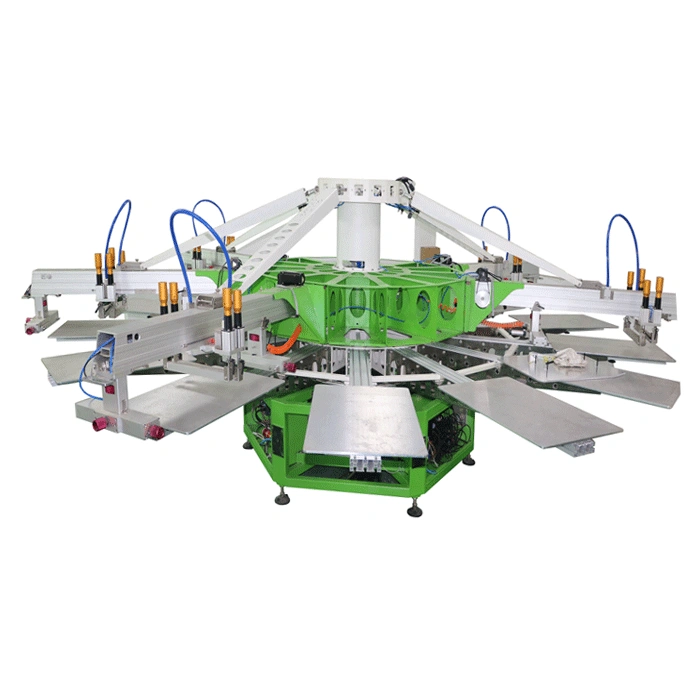

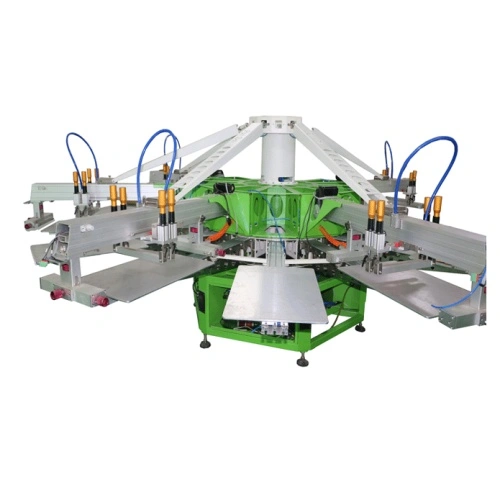

Hot selling octopus Automatic screen printing machine

- Product Item : SA6-4560/10

- Category:Octopus screen printing machine

- Model No. : SA6-4560/10

- Brand : KC

- Type Of Printing Plate : Screen Printer

- Applicable Industry : Garment Shops, Building Material Shops, Machinery Repair Shops, Food &Amp; Beverage Factory, Restaurant, Home Use, Food Shop, Printing Shops

6-color GarmentScreen Printing Machine//Usage and characters

The automation of garment cutting screen printing machines is also a market trend. In terms of overprinting accuracy and ease of operation, the ovalAutomatic Screen Printing Machinehas certain advantages, but it occupies a large area and costs high. For small and medium garment printing factories , The octopus-style multi-color screen printing machine still has a large market space. The multi-color octopus screen printing machine adopts manual loading, that is, the materials and clothing are placed on the workbench by hand. The workbench can have 8-10-12-14 or more according to the number of colors of the machine, and some stations are used for For silk screen printing, some stations are used for drying. In principle, the stations need to be installed with a swing oven to ensure that the surface of the ink is dry and avoid the phenomenon of sticking between colors. The workbench of the screen printing machine can automatically rotate to the next screen printing position to print the next color. In order to improve the accuracy, the screen printing machine adopts a certain mechanical positioning device. At the same time, the upper and lower sides of the screen are controlled by servo motors.The automatic rotary cutting screen printing machine is another representative of the forward and backward movement of the scraper in the type of screen printing machine. We know that theOblique Arm Screen Printing Machineis such a structure, which makes it easier to place and remove products. If you are tired of the hard work of manual screen printing machines and do not plan to buy oval screen printing machines, then you can consider disc screen printing machines.

Catalogue

-

Full automatically operation process ;

-

Total-steel rotating-axis system ensure whirling free and Adaptability.

-

High-strength support pole make the machine structure rigidity.

-

4-color screen printing one time, overprint is precision .

-

Screen frame can be adjustable according to different objects to be printed.

-

Screen frame can be rise up after printing so that printing quality.

-

High-stabilization working table ensure non-shaking when printing;

-

IR Dryer with machine make the clothes drying fast

-

PLC controlling ensure operation more easier

Data

|

SA4-4560/10 Automatically 4-color garment screen printing Machine //Parameters |

|

|

SA6-4565 6-colour automatically rotating flat screen printing machine

|

SA4-4565 4-colour automatically rotating flat screen printing machine

|

|

Works supply |

|

|

Package parameters |

|

|

H.S.CODE |

8443198000 |

|

Certificate |

CE |

Structural Features of Fully Automatic T-shirt Screen Printing Machine

-

Work Table– T-shirts or garment cut pieces are typically single pieces, similar to single sheets in other printing processes. These garments are made of fabrics, which have a loose surface structure and a soft texture, making precise positioning difficult. Additionally, multi-color printing is often required and usually carried out by a single operator. Therefore, the worktable or screen frame must be able to rotate around a central axis. Fully automatic T-shirt screen printing machines typically adopt a rotary table structure. To keep the T-shirt flat during printing, the worktable is coated with platen adhesive, and thus, the worktable is of a flat plate design.

-

Drying Unit– The inks used for T-shirts and garment materials are usually plastisol or silicone-based inks, which require a drying method. The drying unit on fully automatic T-shirt screen printing machines is known as aswing-type dryer. Its principle is similar to other drying lines, but its structure differs. Swing-type dryers are generally used for surface drying during color registration. However, complete drying of the ink still relies on tunnel dryers or air drying.

-

Control Panel– Automation is a prevalent trend in the modern printing machinery industry. Due to the complexity of operations and programming, a user interface panel is essential. Fully automatic T-shirt screen printing machines are no exception. The integrated panel efficiently manages print settings, table rotation, and drying processes, making it easier for operators to adjust processes according to different customer requirements.

-

Positioning Device– Positioning is essential for consistency in the printing process. T-shirts and fabric materials are inherently unstable in size, making precise positioning difficult. However, this can be achieved by placing the fabric on the worktable and using table positioning. For example, determining when the table stops rotating and when the screen frame descends for printing are simple tasks from a mechanical engineering standpoint.

-

Rotary and Oval Table Structures– For most users, a print size of 400×600 mm or around 10 colors is sufficient for T-shirts or garment pieces. However, some customers demand larger sizes and more colors. In such cases, the traditional rotary table structure becomes inadequate. Therefore, many machines on the market now useoval tablestructures. Some of these machines even integrate with digital printers from the outset.

INQUIRY

CATEGORIES

- Inkjet printer

- Roller transfer machine-200mm

- Roller sublimation machine-420mm

- Roller sublimation machine -610mm

- Roller sublimation machine-800mm

- Roller sublimation machine-1000mm

- Laser cutting machine

- Heat press machine

- Ribbon zipper heat transfer machine

- Cloth rolling machine

- Screen printing machine

- Paper and ink

- Spare parts

LATEST NEWS

CONTACT US

Name: lusa zhong

Mobile:+86 13829127980

Tel:+86 13829127980

Whatsapp:008613829127980

Email:sales@zsheatpress.com

Add:Fuma Road, Humen Town, Dongguan City, Guangdong Province, China