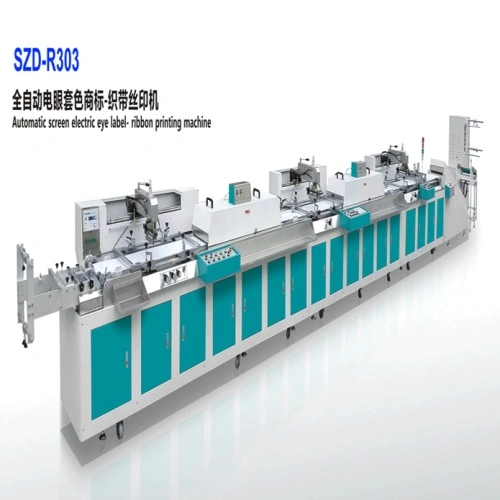

1-2-3-4-5 Colors automatic ribbon screen printing machine

- Product Item : KC-R305

- Category:Ribbon screen printing machine

- Type Of Printing Plate : Screen Printer

- Applicable Industry : Manufacturing Plant, Farms, Printing Shops, Building Material Shops, Construction Works

- Out-of-warranty Service : Video Technical Support, Field Maintenance And Repair Service, Online Support, Spare Parts

- Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) : France, Germany, Viet Nam, Philippines, Brazil, Peru

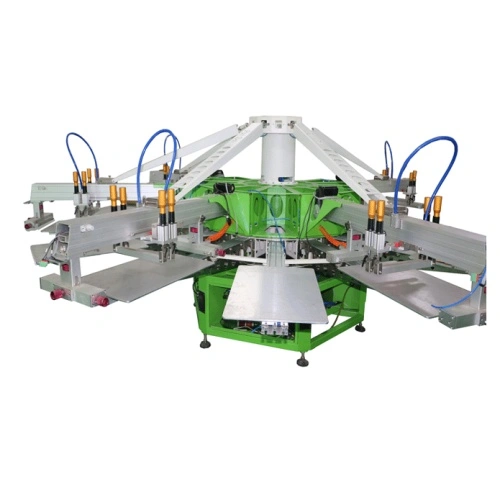

Automatic Ribbon Screen Printing Machine 1 2 3 4 5 colors is an advanced and efficient solution for high-quality textile decoration. Designed for both small-scale operations and large production environments, this versatile device offers precision, speed, and reliability. Whether you are looking to print on ribbon ,belt, or other fabric items, the Automatic Screen Printing Machine 1 2 3 4 5 colors ensures consistent results with minimal effort. The 1 2 3 4 5 color ribbon Screen Printing Equipment combines modern technology with user-friendly features, making it an ideal choice for professionals and hobbyists alike.

The key characteristics of this automatic ribbon Screen Printing Machine include a multi-color printing system that allows for seamless transitions between different hues. With the ability to handle up to five colors in a single operation, this machine significantly reduces setup time and increases productivity. The integrated design ensures smooth ink flow and accurate registration, resulting in sharp and vibrant prints. Additionally, the durable construction guarantees long-term performance, even under heavy use. The user interface is intuitive, allowing operators to easily adjust settings and monitor the printing process in real-time.

This automatic screen printing machine 1 2 3 4 5 colors is equipped with a reliable and efficient motor system that ensures consistent movement across the printing table. The adjustable height feature accommodates various fabric thicknesses, while the precision alignment mechanism minimizes misprints and enhances overall quality. The machine also includes a built-in drying system that accelerates the curing process, reducing the need for additional equipment.

|

|

Product Advantage

1. High-strength steel body, more stable

2. Precision feed platform, a stable paper transport, to ensure perfect print quality.

3. Suction feed platform, holding the paper during printing the same position;

4. industrial piezo print heads, high-precision, low noise, low wear, unattended printing operations;

5 . one brushless servo motor control technology, precise trails, eliminate broken;

6. Automatic cleaning ink stack lift, efficient and complete cleaning effect;

7. External drying device, make sure the ink dried instantaneously;

7. The user-friendly interface, easy to operate;

7. The dual power collecting system and damped discharge system to ensure stable and orderly receipt;

8. High-speed fiber-optic bi-directional communication, data transmission more efficient

Machine details

Structural Features of a Fully Automatic Webbing Screen Printing Machine

-

Worktable – Webbing is a narrow strip product made by fabric weaving, which often has an uneven surface and sometimes exhibits elasticity. To ensure that the webbing does not slip or wrinkle during the screen printing process, a synchronous belt worktable is used. In such a setup, the webbing adheres to the synchronous belt and moves along with it during printing. The synchronous belt is coated with platen adhesive to prevent slippage and deformation of the webbing. To enhance printing precision, the synchronous belt is generally driven by a servo motor.

-

Drying Unit – Screen printing on webbing typically uses plastisol ink or inks suitable for fabrics, all of which require drying. Therefore, a tunnel dryer measuring around 1–2 meters in length is installed after the screen printing unit. Currently, UV inks are not widely used in webbing printing because they have not yet yielded satisfactory results in this application.

-

Control Panel – As a type of automatic roll-to-roll screen printing machine, the webbing screen printer involves relatively complex operations and multiple adjustable parameters due to varying printing processes. A touchscreen control panel is used to efficiently manage the operation and programming of the screen printer.

-

Web Guiding Device – For roll-to-roll automatic screen printers, it is essential to ensure that the pattern is printed uniformly and vertically centered on the webbing at regular intervals. Although automatic web guiding devices are not typically included due to the coarse texture of the webbing, positioning rings are installed on the feed roller to maintain alignment and prevent deviation during transport.

-

Foil Stamping Unit – For users who require foil stamping on webbing, a foil stamping unit can be added at the end of the screen printing machine. Given the fluffy structure of webbing,

INQUIRY

CATEGORIES

- Inkjet printer

- Roller transfer machine-200mm

- Roller sublimation machine-420mm

- Roller sublimation machine -610mm

- Roller sublimation machine-800mm

- Roller sublimation machine-1000mm

- Laser cutting machine

- Heat press machine

- Ribbon zipper heat transfer machine

- Cloth rolling machine

- Screen printing machine

- Paper and ink

- Spare parts

LATEST NEWS

CONTACT US

Name: lusa zhong

Mobile:+86 13829127980

Tel:+86 13829127980

Whatsapp:008613829127980

Email:sales@zsheatpress.com

Add:Fuma Road, Humen Town, Dongguan City, Guangdong Province, China